The Ultimate Guide to Industrial Resin Floor Installers in Manchester

When it comes to finding dependable industrial resin floor installers in Manchester, the stakes are high. After all, the flooring in industrial and commercial spaces needs to handle heavy foot traffic, demanding machinery, and sometimes harsh chemicals. So, how do you ensure you're hiring the right team for the job? Let's break it down.

Why Resin Flooring? A Quick Overview

Resin flooring has become the go-to choice for industrial and commercial settings, offering durability, hygiene, and versatility. From warehouses to hospitals, this type of flooring delivers seamless finishes that can withstand the toughest environments.

Here's what you need to know: resin flooring isn't one-size-fits-all. Options range from high-build coatings perfect for light traffic areas to heavy-duty polyurethane systems designed to tackle the rigours of industrial use. Pricing reflects this, with coatings starting around £8 per square metre and premium polyurethane systems reaching up to £40 per square metre.

Types of Resin Flooring Systems

High-Build Coatings

These are ideal for areas experiencing moderate foot traffic. At about 1000 microns thick, they provide a durable yet cost-effective solution, typically priced between £8 and £12 per square metre.

Self-Levelling Systems

Need a smooth, seamless finish? Self-levelling resin is the way to go. Popular in medical and food processing facilities, these systems create hygienic, non-porous surfaces between 2mm and 4mm thick.

Heavy-Duty Polyurethane Screeds

For environments like factories or industrial kitchens, heavy-duty polyurethane systems are unbeatable. They're thicker (6mm to 9mm) and offer exceptional resistance to chemicals and mechanical wear, costing between £30 and £40 per square metre.

What to Look for in an Industrial Resin Floor Installer

Hiring the right team makes all the difference. Here's what to check:

Credentials and Certifications

Certified installers will adhere to top industry standards, including ISO9001 and ISO14001, ensuring quality and environmental compliance. For polyurethane systems, look for ISOPA and ALIPA certifications, which guarantee safe handling of materials like diisocyanates.

Experience in Industrial Settings

Industrial environments have unique demands. Seasoned installers will understand these and customise their approach to suit heavy-duty applications or hygienic settings.

Comprehensive Site Preparation

Good installation starts with a solid foundation. Professional installers assess the substrate for moisture, structural integrity, and surface defects before laying the resin.

The Installation Process: What to Expect

Site Preparation

This step is crucial. Installers begin by thoroughly inspecting the concrete substrate. Any flaws, moisture issues, or contaminants are addressed to ensure proper adhesion.

Application Techniques

The method varies depending on the resin system. Multi-layer systems, for example, require careful layering to achieve a thickness of 1mm to 2mm, while heavy-duty systems need more substantial application.

Curing Time

Most resin flooring requires 24–48 hours to cure. While the overall timeline depends on the project's size and complexity, installations typically take 3–5 days from start to finish.

Sector-Specific Solutions

Industrial Applications

In manufacturing plants and warehouses, resilience is key. Flowable resin floors, ranging from 4mm to 6mm thick, are perfect for these settings. They offer excellent impact and wear resistance, costing around £25 to £35 per square metre.

Commercial Environments

For businesses like healthcare facilities or labs, self-smoothing resin floors provide both aesthetic appeal and practicality. Their seamless design ensures hygiene and easy maintenance.

Maintaining Your Resin Floor

Resin flooring isn't just about the initial installation; proper maintenance ensures longevity.

Routine Cleaning and Inspections

Regular cleaning and biannual professional inspections help catch minor issues before they escalate. In high-risk environments, quarterly checks may be necessary to maintain strict safety and hygiene standards.

Aftercare Services

Top-notch installers won't leave you hanging. They'll provide guidance on maintenance routines and offer aftercare services to maximise your investment.

Frequently Asked Questions

How long does a resin floor last?

With proper care, a professionally installed resin floor can last 10–20 years or more. Heavy-duty systems are especially durable in industrial settings.

Can resin flooring be installed over existing concrete?

Absolutely, as long as the concrete meets specific criteria. Installers will check for moisture, stability, and surface quality to ensure successful adhesion.

What safety qualifications should an installer have?

Look for ISOPA and ALIPA certifications, alongside ISO9001 and ISO14001 compliance. Additional accreditations, such as FeRFA membership, are also a plus.

How long does installation take?

Most projects are completed within 3–5 days, including preparation, application, and curing time.

How often should resin flooring be maintained?

For high-traffic areas, biannual inspections are recommended. Environments with strict hygiene requirements may need more frequent checkups.

Conclusion

Choosing industrial resin floor installers in Manchester isn't just about cost—it's about finding a team with the expertise, certifications, and commitment to deliver lasting results. Whether you're upgrading a warehouse or outfitting a medical facility, partnering with the right professionals ensures your flooring investment stands the test of time.

So, take the time to vet potential installers, ask about their qualifications, and review their past projects. It's a decision that pays dividends in durability, performance, and peace of mind.

Resin Flooring Installations in Other Cities

Resin Flooring Installers in ManchesterResin Flooring Installers in Sheffield

Resin Flooring Installers in Coventry

Resin Flooring Installers in Preston

Right here at Regal Paints, we provide both equally epoxy floor sealer and an epoxy leading coat in many different well-known colors. It is recommended that you use these collectively to acquire the ultimate in protection and toughness. These epoxy paints are advisable to be used in large-visitors locations and remain resilient even in locations which might be driven on by cars and trucks. Our choice of wonderful epoxy paint is exactly what brings buyers to buy at Regal Paints.

When using, pour the pumice in to the paint and mix carefully. After mixing, utilize the paint instantly. Implement the paint by using a roller to achieve a dependable finish. A all-natural stone alternate to plastic microbeads.

Polyurethane resin flooring presents a flexible and robust Option for a variety of environments. Our staff at Resin Flooring Contractors specialises in installing polyurethane resin floors that are the two purposeful and visually appealing.

Incorrect surface preparation is the 2nd commonest reason for a lousy complete – that you are not likely to get the very best finish should you paint in excess of oil or grease or grit – so a fantastic cleanse to start with tends to make a big variation on the finish and sturdiness of the floor. To summarise, regardless if you are intending to use garage floor paint to hide those aged oil stains, an auto park to keep it clean up and dirt no cost or to give colour and safety in your floor undertaking there actually is practically nothing much better with these a variety of selections than a fantastic Epoxy Floor Paint applied by roller next the producers Directions. Valuable details for applying Epoxy Floor Paint - Cold Weather conditions Tips

The sole true cons are aesthetics and set up approach. Even self levelling epoxy coatings normally takes a long time to dry, so they're going to have to be poured and afterwards left to established for some time before the floor surface can be utilized once again.

From resin coatings more than polished concrete floors to complete epoxy resin pours, we can offer seamless, non slip surfacing for just about any place.

We control all facets of your venture less than just one roof, guaranteeing well timed completion to the very best specifications. By using a devoted job manager, we assurance transparency in expenses and promise to match or defeat like-for-like quotes. Take pleasure in our retail structure providers, and rest assured that honesty and integrity guideline our process.

Whether or not it’s for industrial, commercial, or household initiatives, we blend progressive methods with business very best practices to ensure a seamless set up approach.

Nonetheless, the wonderful customer support is what keeps our consumers coming back time and again. Regardless if you are a do-it-yourself-er in search of assistance on painting your garage, or you're in control of the inside of a tremendous warehouse facility, we're here for yourself. Search our choice on line or Get hold of us with any queries or issues. We've been often happy to help together with your paint preference or Should you have questions about the appliance procedure. Epoxy Floor Paint – a versatile Alternative to a lot of problems

When working with, pour the pumice in to the paint and blend thoroughly. Soon after mixing, utilize the paint right away. Implement the paint with a roller to realize a dependable finish. A organic stone alternate to plastic microbeads.

If you're Industrial Resin Floor Installers in Manchester doubtful about any of these concerns, remember to Get hold of us and we will be pleased to discuss the venture with you. Together with the above mentioned, remember to note that In case you are working with a multi-coat Epoxy Resin Floor Paint, you should make certain that the temperature needs of each different product in just that you could be employing is ideal.

Initially it is actually worthy of investing a couple of times to provide an summary of The fundamental chemistry of these kinds of products as this helps you to realize why They can be so versatile. All Epoxies are based upon a resin program made up of epoxide reactive groups, the most typical one in use nowadays is 1 depending on bisphenol A, Despite the fact that Other folks based upon hydrogenated bisphenol A, Bisphenol File or S and so known as reactive diluents also exist. This is actually the creating block of your program and delivers The main element Gains we are trying to find particularly chemical resistance, energy, adhesion to an assortment of various surface varieties (nearly anything from metal and concrete to Wooden and composite decking on boats).

They took time to comprehend our vision and delivered pro tips on the most effective resin options to obtain the desired outcome.

Resin flooring resources offer you several Rewards and are mounted in a wide range of distinctive environments like meals factories, industrial units, engineering, retail and industrial outlets and healthcare facility predicaments. Ashley Resin Flooring will make sure the ideal product or service is specified in Every single condition.

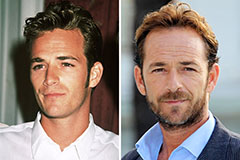

Luke Perry Then & Now!

Luke Perry Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Hailie Jade Scott Mathers Then & Now!

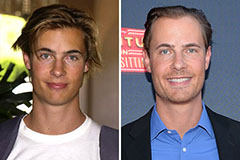

Hailie Jade Scott Mathers Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now!